In the world of manufacturing, innovation is a constant pursuit. Technologies that promise to revolutionize the industry are met with anticipation and skepticism. One such technology that has gained substantial momentum in recent years is 3D printing, particularly when it comes to metals.

In this discussion, we'll explore how 3D printing metal technology is shaping the future of manufacturing and why it is rightly regarded as a disruptive force.

What is 3D Printing?

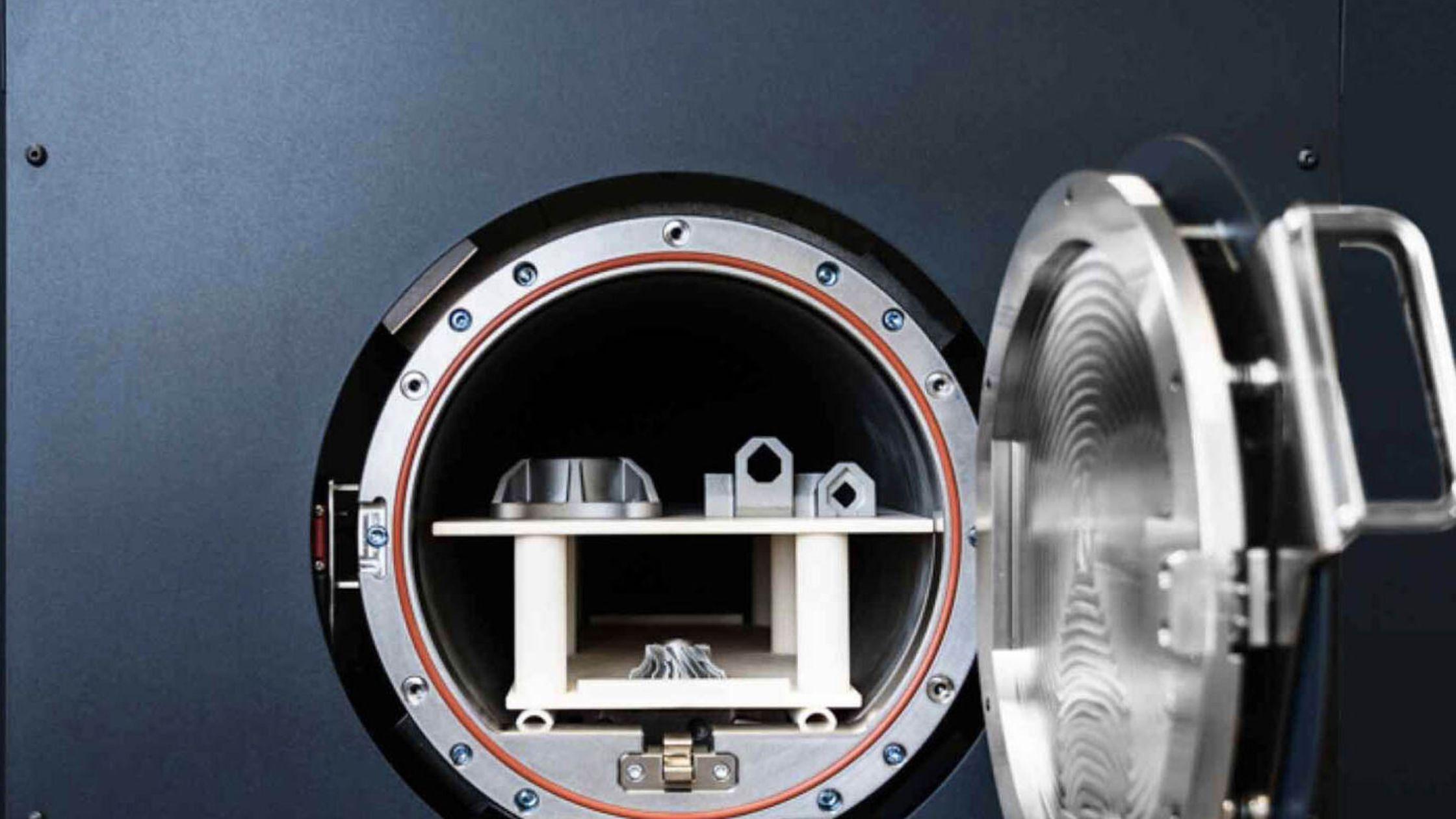

3D printing, or sometimes also known as additive manufacturing, is a process that constructs three-dimensional objects by adding material layer by layer. Unlike traditional subtractive manufacturing methods that involve cutting away material, 3D printing starts with nothing and builds the object from the ground up.

This fundamental difference has unlocked endless possibilities, and 3D printing has now evolved into a versatile technology applicable in various industries, from healthcare to aerospace.

3D Printing Metal Technology: A Game-Changer

3D printing with metals is not a new concept, but it has seen significant advancements in recent years. Traditionally, plastics and polymers were the primary materials used in 3D printing. However, the ability to print with metals has opened up a whole new world of possibilities. The process involves using metal powders, often in combination with a binding agent, to create intricate, high-strength metal parts.

Complex Geometries: One of the primary advantages of 3D printing metal technology is the ability to create highly complex and intricate designs that would be impossible or incredibly costly to produce using traditional manufacturing methods.

Reduced Waste: Unlike subtractive manufacturing, which generates significant material waste, 3D printing is more environmentally friendly as it generates minimal waste.

Rapid Prototyping: It allows for quick prototyping and iteration, reducing lead times in product development and design.

Customization: It enables mass customization, where each part can be tailored to individual specifications, making it ideal for industries like healthcare and aerospace.

Applications of 3D Printing with Metals

The applications of 3D printing metal technology are wide-ranging and continually expanding. Here are some industries and sectors that are benefiting from this transformative technology:

Aerospace

In the aerospace industry, 3D printing technology is enabling the production of lightweight yet highly durable components. This not only reduces fuel consumption but also enhances the overall efficiency and safety of aircraft.

Healthcare

The medical field is leveraging 3D printing technology for the creation of custom implants, prosthetics, and orthopedic devices. This personalized approach improves patient outcomes and quality of life.

Automotive

3D printing is being used to manufacture intricate and lightweight components, leading to improved fuel efficiency and reduced emissions. This technology is also supporting the development of electric and autonomous vehicles.

Architecture

Architects and construction firms are exploring the use of 3D printing technology to create complex and sustainable building structures. This not only speeds up construction but also reduces material waste.

Defense

The defense industry benefits from the ability to rapidly produce customized components and equipment, helping to improve military readiness and response times.

Disruptive Technology: The Impact of 3D Printing with Metals

The traditional manufacturing process often involves a series of steps that can be time-consuming and costly. From tooling and molds to machining and assembly, each stage introduces opportunities for delays and errors. 3D printing disruptive technology disrupts this chain by enabling the direct fabrication of complex parts, eliminating the need for expensive molds and tooling.

Supply Chain Transformation

The on-demand nature of 3D printing with metals can revolutionize supply chains. Instead of stockpiling spare parts and components, manufacturers can print them as needed. This could reduce the costs associated with inventory management and logistics.

Economic Impact

The economic implications of 3D printing disruptive technology are significant. This disruptive technology has the potential to create jobs in the fields of design, materials science, and 3D printing services. Furthermore, it can reduce the reliance on offshore manufacturing by making it economically viable to produce complex components domestically.

The End Note

3D printing metal technology is, without a doubt, a disruptive force in the world of manufacturing. Its ability to create complex, customized, and high-strength metal parts has far-reaching implications, from revolutionizing supply chains to reducing waste and reshaping the job market.

While challenges remain, the trajectory is clear: the future of manufacturing is being shaped by 3D printing with metals. As this technology continues to evolve and mature, its impact will only become more profound, solidifying its place as a cornerstone of the fourth industrial revolution.